When it comes to maintaining a successful business, it’s crucial to maintain a competitive edge and keep your processes running efficiently. In material handling business, it’s essential to have smooth, efficient processes. Whether you’re manufacturing products, a shipment facility, or dealing with lifting and loading tasks, using the right material handling equipment is crucial to your operations. Our article dives into some of the essential equipment that you need to keep your material handling organisation up and running. To learn more about the equipment you can use to improve your workplace efficiency, keep on reading our blog.

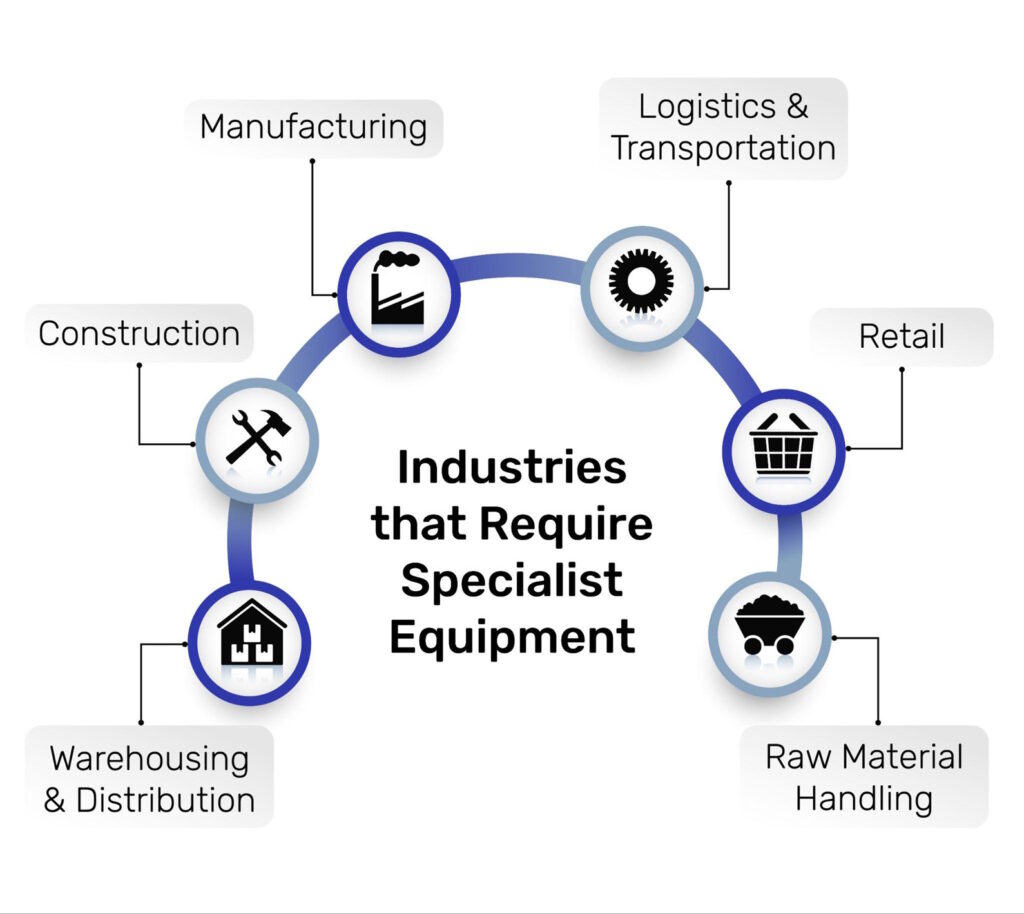

Industries That Require Specialised Material Handling Equipment

There are various industries that can benefit from the use of specialised equipment. Some of those industries include:

Essential Material Handling Equipment For Your Site

While each site can differ, and different industries will have varying requirements, we’ve curated a selection of the most common and useful equipment that you could have on your site. By having a variety of material handling equipment, each process on these sites can be made simpler or more efficient, improving the overall productivity of material handling facilities. Read below to learn more.

Forklifts

Forklifts are an essential part of any warehouse or distribution centre, manufacturing organisation or construction site. They are ideal for moving, stacking and lifting heavy materials over short distances (within warehouses etc). In retail settings, forklifts can be ideal for moving stock and other large items. They may be used to unload delivery tricks, move products on shelves or organise pallets in storage areas. They come in many various types and sizes, so that you can find the right forklift for your operational needs.

Conveyors

Conveyors are another excellent tool that warehouses and manufacturing organisations can use to speed up processes and reduce manual labour efforts. Conveyor systems will move goods from one area to another on a continuous conveyor belt. For retail stores or manufacturing plants, this is ideal for handling packaged goods. In manufacturing plants, conveyors transport parts through the different assembly stages, helping to speed up assembly and reduce the manual effort of employees to move goods.

Scissor Platform Lifts

Scissor platform lifts, also known as goods lifts, are specifically designed for moving loads and products at a height. Their name comes from the criss-cross, or scissor like mechanism that causes the lift to move up and down. Scissor platform lifts are strictly for transporting materials, and not people, unlike scissor lifts. They can be found in warehouses, docking bays, construction and industrial settings, where they are used to move loads with a high weight capacity. In environments where heavy or bulky items need to be transported vertically, they are extremely useful for material handling.

Work Positioners

Work positioners are mobile surfaces that would be used to lift heavy objects in tighter spaces, or sometimes outdoors. They have adjustable heights and are extremely versatile. Work positioners are more compact than forklifts or other lifting equipment, which makes them ideal for more confined spaces. Using work positioners is safer and more efficient, especially in hard to reach spots, and takes the physical strain off of employees who could potentially sustain an injury.

Dock Equipment

Dock equipment is used in warehouses, shipment facilities and other businesses to efficiently load and unload goods. These operations will rely heavily on well-equipped docks, so that they can move goods in pallets safely, or in confined spaces. Dock equipment includes items such as dock levellers, seals, bumpers and shelters, which are all needed to effectively load/unload tricks. Quality dock equipment makes for a safe loading or unloading of goods, allowing forklifts to move the goods to where they need to be.

Pallet Jacks

A pallet jack is a useful tool to have on any site, and is primarily used for transporting materials that have been stacked onto pallets. Pallet jacks are machines with twin forks, which slide under the pallet. Hydraulic force is used, by pumping a handle, to lift the pallet, having it ready for transportation. Pallet jacks are ideal for spaces where forklifts are too bulky, or cannot get into the space. In retail stores, pallet jacks might be used to transport stock from storage areas to the shop floor, and in smaller warehouses they may be used to transport small but heavy loads more easily.

Storage Containers & Bins

Storage containers and bins are useful items to have on your site, especially for organisation and storage. While they aren’t necessarily tools or machinery, storage containers and bins can be used effectively on large sites to store smaller items or goods that don’t require pallet storage. These containers can then be moved via hoists or cranes, depending on their size. This can help large facilities to stay organised, rather than having goods in random places. It will also help with freeing up floor space, and maintaining a safe work environment for employees.

Hoists & Cranes

Hoists and cranes are another example of essential equipment for warehouses, manufacturing facilities and shipping organisations. They are essential for lifting and moving heavy loads that can not be transported by forklifts or manual labour. These loads tend to be heavy duty items, which are vital for construction projects and lifting heavy machinery. Cranes are used to unload and load in various applications, and hoists can be used for maintenance tasks on a site. They make heavy duty processes much easier and much safer for employees. Appropriate training and safety protocols should be provided to anyone working on site with a crane or hoist.

Pallet Levellers

Pallet levellers are a type of mechanical device, which help to load and unload goods that need to be palletised. These devices will automatically raise, lower or tilt pallets to comfortable working heights. Rather than putting strain on employees, who could potentially suffer from injuries, pallet levellers keep the top of the pallet at an ideal level, so that employees can manually load or unload it. This helps to minimise the risk of injury, repetitive strain, or an employee handling an entire pallet, which would be too heavy to work with.

AGVs

AGVs, also known as automated guided vehicles, are a type of machine, which offer autonomous transportation of goods within a facility. These machines, or robots, use navigating sensors and predefined routes to transport goods and carry out tasks. AGVs are extremely useful on large sites, and could be the future of various industries. Their ability to operate without human intervention allows businesses to minimise labour costs, and employees can focus their time on other tasks. In assembly stations, and e-commerce warehouses, AGVs can be used to retrieve products and transport the relevant items around a facility.

Scissor Lift Table: Trusted Suppliers Across The UK

Our article has thoroughly explored how different types of material handling equipment can be used in your workplace to enhance workflow and improve efficiency. These tools and equipment will not only increase workplace productivity, but enhance employee safety and overall business output. In such competitive markets, material handling organisations can use specialised equipment to stand out from other businesses, and be the number one choice.

Here at Scissor Lift Table, we supply a range of quality items across the UK. From scissor platform lifts to work positioners, we offer a selection of quality equipment for your workplace. Browse our site for more information regarding our products, or reach out to our team today for further information. Get in touch with us to speak to our team, we will be happy to help you find exactly what you’re looking for.