Electric scissor lift tables are critical pieces of equipment for lifting and positioning heavy loads across a wide range of industries. To ensure the longevity and optimal performance of scissor platform lifts, regular maintenance and servicing are a must.

In this article, we’ll discuss the best practices for maintaining electric scissor lift tables, covering routine tasks like inspections, lubrication and part replacement. Following recommended maintenance guidelines helps extend the lifespan of your equipment, maximise its efficiency and avoid costly repairs.

What Are Electric Scissor Lift Tables and How Do They Work?

Electric scissor lift tables are mechanical devices that use an electric motor to raise and lower heavy loads to different heights. The lift platform sits on top of cross-linked legs. When the electric motor is turned on, hydraulic fluid or compressed air fills the cylinders and pushes the legs apart. The scissor mechanism extends to lift the table or retracts to lower it.

These scissor platform lifts are commonly used in environments like warehouses and assembly lines to assist workers with lifting tasks. Electric scissor lift tables can easily lift heavy and bulky objects, providing a safe, reliable method for handling and positioning loads that reduces the risk of manual handling injuries.

Why Is Maintenance Work Important?

Routine maintenance is essential to keep electric scissor lift tables operating safely and efficiently. A lack of maintenance and servicing can cause key components to wear out more quickly, leading to frequent repairs or replacements. By conducting regular inspections, you can identify any issues early on to avoid unexpected breakdowns.

Additionally, ongoing maintenance helps protect your equipment and promotes a safer work environment. Routine care ensures the platform scissor lift continues to run smoothly, minimising the risk of accidents and extending its lifespan. Proper equipment maintenance is critical to ensure companies comply with safety regulations.

Understanding the Different Types of Maintenance Work

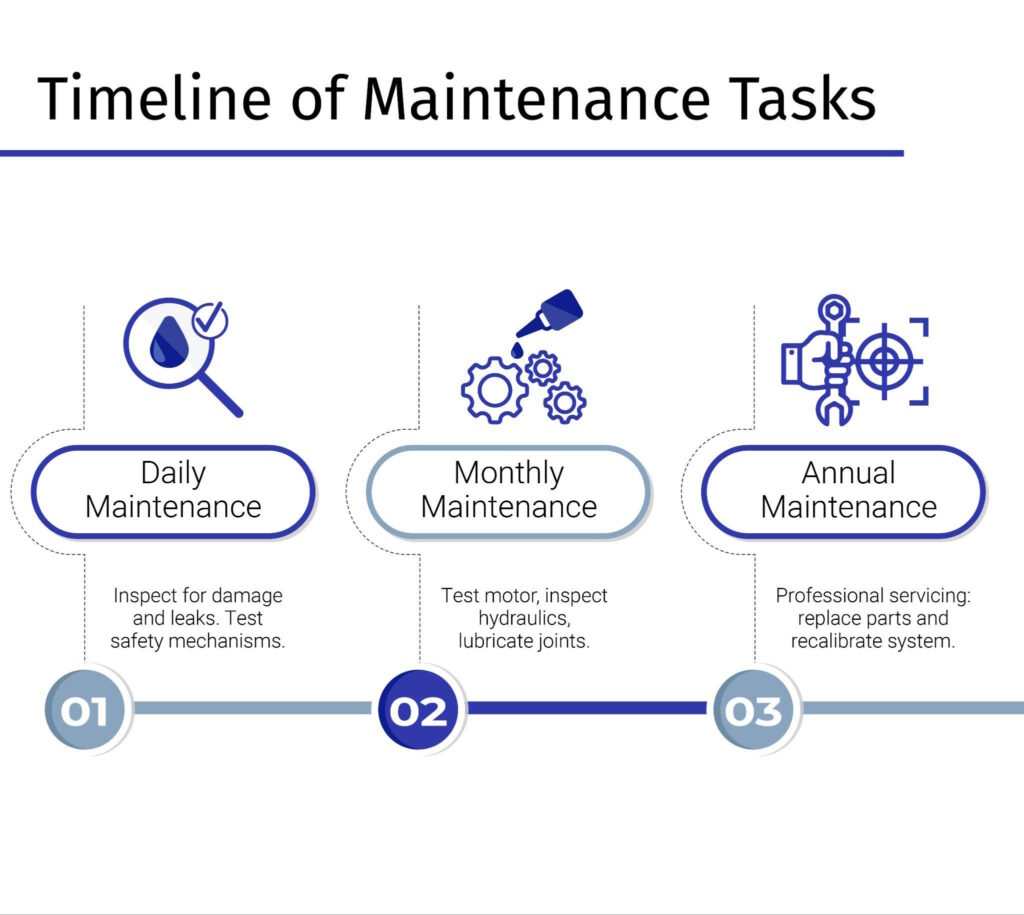

Maintenance tasks for electric scissor lift tables fall into three main categories: daily, monthly and annual, each referring to the frequency they must be carried out.

Daily maintenance involves conducting visual inspections for damage and leaks, and ensuring all safety mechanisms are functional. Monthly maintenance requires more thorough checks, like testing the motor, inspecting hydraulic systems and lubricating joints. Typically, annual maintenance refers to professional servicing. A comprehensive examination is carried out, replacing any worn-out parts and recalibrating the system to meet safety standards.

Each stage of maintenance care contributes to the performance and longevity of your scissor lift table, ensuring reliable operation over time.

Essential Maintenance Tasks

To keep your electric scissor lift table in proper working condition, a number of maintenance tasks must be completed by a competent person. Let’s take a look at these tasks in more detail.

Regular Inspection

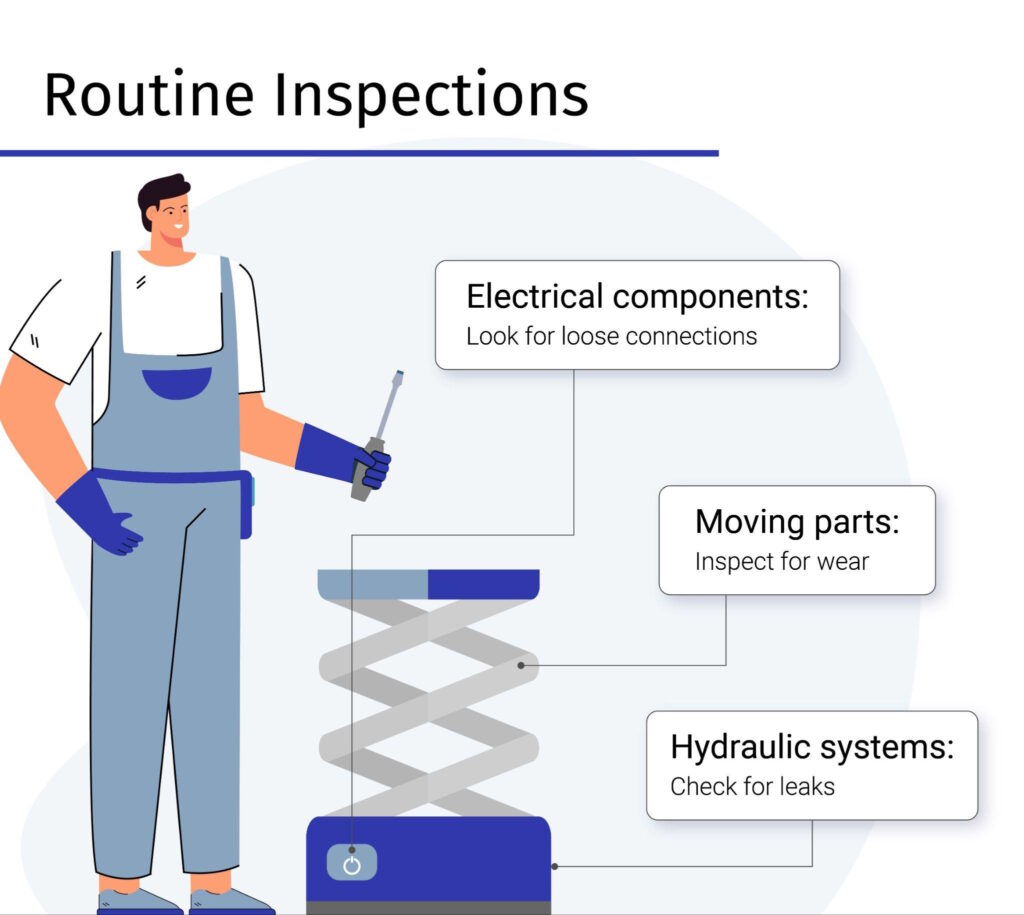

Routine inspections are the foundation of effective maintenance care for hydraulic scissor lift tables. These checks focus on the lift’s moving parts, hydraulic systems and electrical components, looking for any early signs of wear and tear or damage. Check for any leaks, loose connections or worn-out parts.

Any irregularities can decrease your electric lift table’s performance and lead to breakdowns or safety risks if issues are not dealt with quickly and effectively. Regular inspections prevent minor issues from becoming major issues and help ensure the scissor platform lift table is functioning at optimal capacity.

Lubrication

Proper lubrication is critical for smooth operation, ensuring the electric lift table runs smoothly, reducing downtime and extending its lifespan. Regularly apply lubricant to key components like the pivot points, hinges and hydraulic cylinders to reduce friction and wear.

Without proper lubrication, components can become damaged, leading to costly repairs and reduced performance. For best results, make sure to check your manufacturer’s guidelines for the recommended lubrication schedule and the appropriate lubricant products.

Hydraulic System Maintenance

Hydraulic systems are the key component of scissor platform lifts. Regularly check hydraulic fluid levels and inspect hoses, fittings and seals for leaks. Maintaining the hydraulic system prevents lifting issues and ensures the table functions correctly.

It’s important to check the hydraulic fluid level and quality to ensure it meets the manufacturer’s specifications and replace hydraulic fluid and filters when necessary. Proper hydraulic system care is vital for smooth, reliable lifting and ensures long-term efficiency.

Safety Mechanisms

Safety features, such as limit switches, emergency stop buttons and safety rails, must be checked regularly to ensure they function as intended. These mechanisms are in place to protect operators and prevent accidents, so it’s critical they remain in good condition and unobstructed or damaged.

Test these features periodically to check their functionality and ensure your electric lift table stays compliant with safety regulations. Any malfunctions should be addressed immediately to maintain a safe work environment and avoid workplace injuries.

Cleaning and Debris Removal

Keeping the electric scissor lift table clean is another important part of maintenance. Debris and dirt can accumulate on scissor platform lifts, which can interfere with their operation. Regular cleaning removes the buildup of dirt, debris and any other materials that can affect performance or safety. Remove any obstructions from the scissor arms and make sure the platform remains clean and uncontaminated. A well-maintained and clean scissor platform lift table not only looks better but also lasts longer.

Professional Servicing

While regular in-house maintenance can prevent and detect many issues, professional servicing is essential for a more thorough inspection and repair. Qualified technicians have the expertise and knowledge to assess the electric lift table’s condition, make necessary adjustments, replace worn parts, and ensure compliance with industry standards.

This level of inspection and servicing should be scheduled annually to fine-tune the lift table for peak lift performance. Professional maintenance helps prevent major breakdowns and ensures the longevity of your electric scissor lift table.

Replacements

Certain components of your electric scissor lift table, such as hydraulic valves, electrical relays and bearing bushes, should be replaced after extensive use. It’s recommended to replace these components every 200,000 lift cycles to ensure the equipment operates efficiently and safely. By replacing only worn parts rather than the entire lift table, you extend the equipment’s lifespan and save on replacement costs.

Maintenance Top Tips

In conjunction with the necessary routine inspections and professional servicing, following these additional tips can help you maximise the efficiency of your electric lift table maintenance.

Manufacturer Information

Electric lift tables come with comprehensive documentation with instructions for the recommended maintenance tasks. These guides contain detailed explanations, diagrams and images to help operators carry out essential upkeep effectively.

Documentation and Record-Keeping

Keeping detailed records of all maintenance tasks, inspections and repairs is crucial. Regular documentation helps you stay on track with maintenance schedules, identify recurring issues, and ensure compliance with safety regulations. This ensures the long-term safety and reliability of the lift table and provides a valuable reference for maintenance and servicing work in the future.

Training and Operator Awareness

Proper training is essential for maintaining a safe and effective environment when working with scissor platform lift tables. Operators should be knowledgeable about maintenance and how to spot the early signs of wear or malfunction.

Training also includes best practices for operating the lift, adhering to safety protocols and reporting any issues immediately. Well-informed and trained operators are essential to ensuring the longevity and safety of electric scissor lift tables.

Scissor Lift Table

To get the most out of your electric scissor lift table, it’s vital to follow a structured maintenance routine. Regular upkeep, from daily inspections to annual servicing, will ensure your lift table operates smoothly and safely, reducing the risk of breakdowns and costly repairs.

At Scissor Lift Table, we pride ourselves on delivering durable and efficient lifting equipment, from electric scissor lift tables to lift and tilt tables. Our knowledgeable team is available to provide expert guidance on all aspects of maintenance, ensuring your scissor platform lift stays in optimal condition for years to come.

For more information about our products and services, get in touch with our team today!