Factory work of all kinds relies on a wide array of equipment to facilitate effective manufacturing and assembly processes. Comparable modes of manufacturing are utilised across these sectors in order to curate a workable end product, whether these assembly lines are used to build cars, construction tools or computer technology.

As such, in this kind of environment, tools such as scissor lift tables and pallet lifts are invaluable. When it comes to promoting assembly line efficiency, this kind of precision equipment can be incredibly helpful. pallet lifts in particular can be used to adjust pallets to an appropriate working height, helping to streamline loading, unloading and assembly work.

Read on to find out more about how pallet lifts can be used to enhance your everyday workplace efficiency.

What Is A Pallet Lift?

A pallet lift is a purpose-built tool designed to assist in the handling of various loads within a manufacturing setting. These devices tend to employ similar mechanisms to scissor lift tables, where they have a platform and base connected to a pair of scissor legs. As with a scissor lift table, this crisscross structure extends and retracts in order to move the platform up and down.

In particular, a pallet lift consists of a set of springs designed to adjust to the weight and height of a loaded product. The platform can then adjust automatically as the weight and density of the object change, meaning it can maintain a safe working height for loading and unloading efforts.

This ability to automatically raise, lower or tilt pallets helps to ensure proper alignment, minimising the strain placed on workers during the manufacturing process. In this way, pallet lifts can be used to streamline assembly line practices whilst optimising workplace safety.

How Pallet Lifts Enhance Efficiency

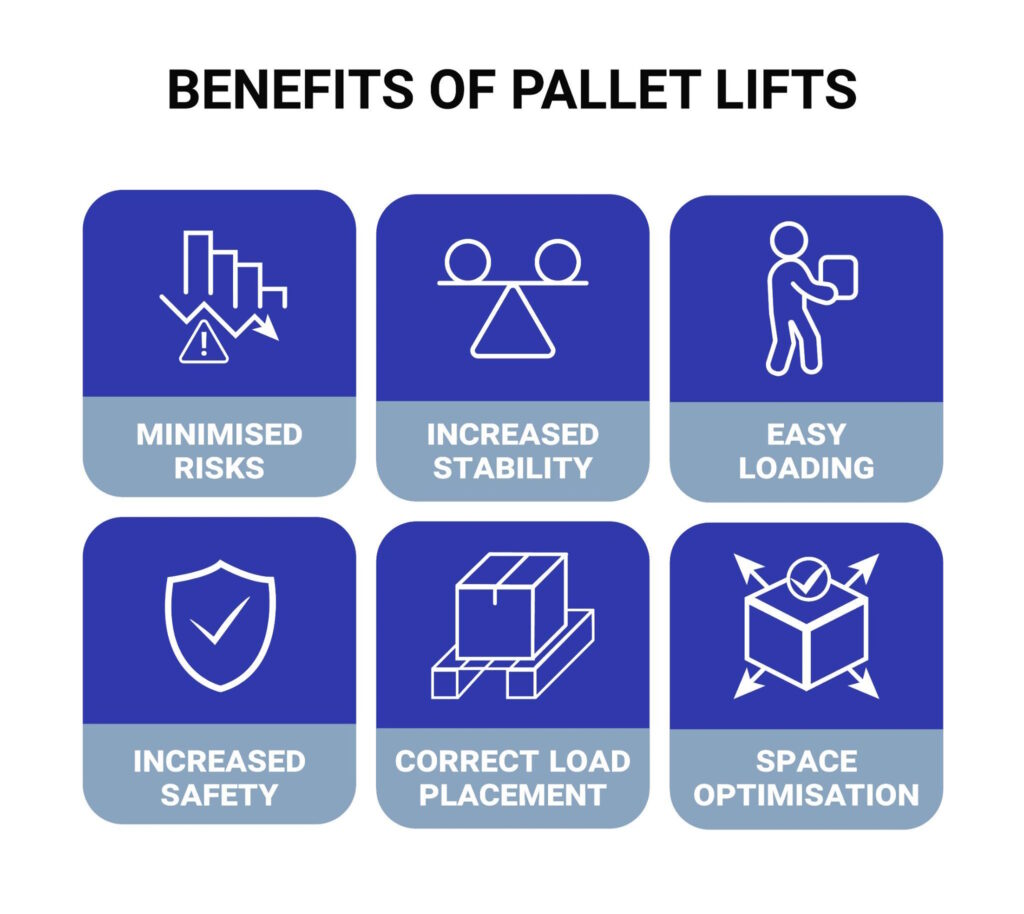

There are numerous ways in which pallet lifts can enhance efficiency in the workplace, where these are discussed below:

Minimal Injury Risk

A key advantage of using pallet lifts is that they can be used to reduce back problems experienced by the workforce. As this device will bring pallets to an optimal height, workers won’t have to bend or lift beyond a safe limit, helping to conserve their spinal health. This will help to enhance workplace efficiency by reducing instances of sickness and creating a happy and healthy workforce.

Increased Stability

Pallet lifts are also ideal for increasing stability in a manufacturing environment. Their automatic levelling technology is designed to keep pallets in position as loads are worked upon, whether parts are being fitted, adjusted or packed. As such, this makes precision manufacturing work easier to complete to a high standard, improving efficiency across the production line.

Easy Loading & Unloading

Working with pallets tends to involve lots of loading and unloading, as items are added to and removed from the assembly line. A pallet lift makes this work much easier for employees by ensuring that pallets are in an optimal position. This means that workers don’t need to strain or manually adjust pallets, contributing to a more efficient manufacturing environment.

Improved Safety

In addition to reducing back strain, pallet lifts also contribute to workplace safety more widely. This is because they ensure that pallets are stable and ergonomically positioned, helping to create a safe working environment for employees. As such, risks of injury related to manual handling are reduced, contributing to general workplace efficiency along the assembly line.

Correct Load Placement

Pallet lifts are designed to automatically adjust depending on the load in question, meaning that the correct placement can be achieved with minimal intervention by the workforce. Correct load placement is essential for precision manufacturing work and more complex assembly tasks, where pallet lifts can help to ensure that this process is completed with minimal downtime.

Space Optimisation

Investing in pallet lifts for your warehouse will also allow you to optimise your use of space. This is because pallet levelling technology can help you to make the most of your vertical storage, whilst allowing for denser pallet configurations. As such, you can retain more items on site, without worrying about additional storage costs.

Essential Safety Tips When Working With Pallet Lifts

In order to optimise workplace efficiency, it is important that all equipment is utilised according to strict safety guidelines. This includes proper handling of pallet lifts, where these devices should be used carefully in order to prevent accidents and prolonged downtime.

Some essential safety tips include:

Staff Training

All workers must be familiar with the equipment they are using in a manufacturing environment, where training should be completed by new hires and on a regular basis by long-term employees in order to refresh key knowledge. Good training programmes will cover a variety of health and safety factors, including proper handling techniques and how to react in an emergency.

Equipment Inspections

Additionally, all manufacturing equipment should be inspected before use to ensure that everything is in good working order. This process may include noting any broken parts, corroded surfaces or loose screws, all of which can endanger users and lead to serious malfunctions. If a fault is discovered, then this should be recorded in a designated log book or via an online system so that the issue can be addressed in a timely manner.

Load Limits

Most lifting equipment will come with a stated load limit that should not be exceeded for any reason. Scissor lift tables and pallet lifts will have a capacity range listed in the user manual, where this may also be restated on the equipment itself. As such, workers should remain aware of these load limits at all times, exercising caution when attempting to manoeuvre notably heavy products.

Cautious Handling

Workers should also exercise appropriate caution at all times when using pallet lifts. This means approaching equipment slowly and steadily, ensuring that all safety procedures have been followed before attempting to engage the machinery at hand. Users should also keep fingers away from machinery edges, conducting thorough visual inspections and checks prior to the initiation of potentially dangerous processes.

Scissor Lift Table: Premium pallet lifts For Your Workplace

We can provide you with an ergonomic pallet lift table in order to enhance efficiency across your assembly line, where our pallet positioners are designed to be both hardwearing and safe to use.

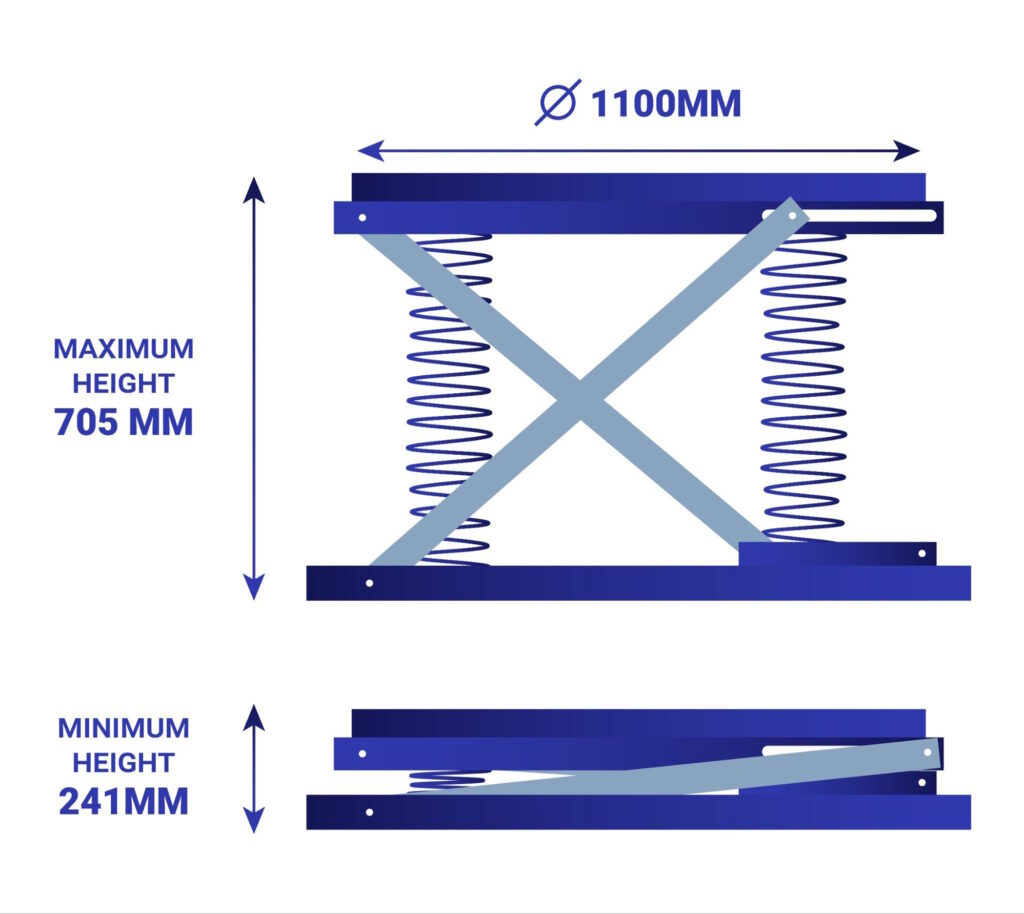

In particular, you may wish to consider the Edmolift pallet lifts PL 2002, where this exceptional model features:

- A 150 to 2000 kg capacity

- A height range of 241 to 705 mm

- A platform size of 1100 mm in diameter

This height range and capacity is ideal for a variety of manufacturing tasks, whether you’re developing a busy assembly line or are looking to improve efficiency in your warehouse.

Designed to provide both strength and stability, our pallet lifts help to reduce the risk of injury and strain by automatically positioning load height. These levellers will help to make working with pallets so much easier for your team, making loading and unloading faster, safer and more efficient.

Our pallet lifts and scissor lift tables have been trusted by industry professionals for decades, where you can depend on us for innovative solutions that drive output and efficiency across your site.

Beyond this, we also supply bespoke scissor lift tables according to your design specifications, so we can provide you with the perfect model for your premises.

Get in touch with our expert team today to discuss your unique requirements, or visit our FAQ page to learn more about our scissor lift tables and pallet lifts.