Fantastic additions to any warehouse or business, scissor lift tables can be used across various industries. To ensure they are functioning properly, however, it’s important to carry out regular and thorough maintenance on these tables.

In this article from Scissor Lift Table, you can learn how to care for your helpful lifting equipment.

An Introduction to Scissor Lift Tables

Found in warehouses across the UK, scissor lift tables are helpful additions to companies that routinely need to lift heavy goods upwards. The tables are characterised by their hydraulic or air systems, attached to metal legs that can propel upwards.

These hydraulic lift tables are designed solely for the use of material goods. They come in a variety of designs and styles, providing effective ways for each company to lift their products tailored to their set of needs.

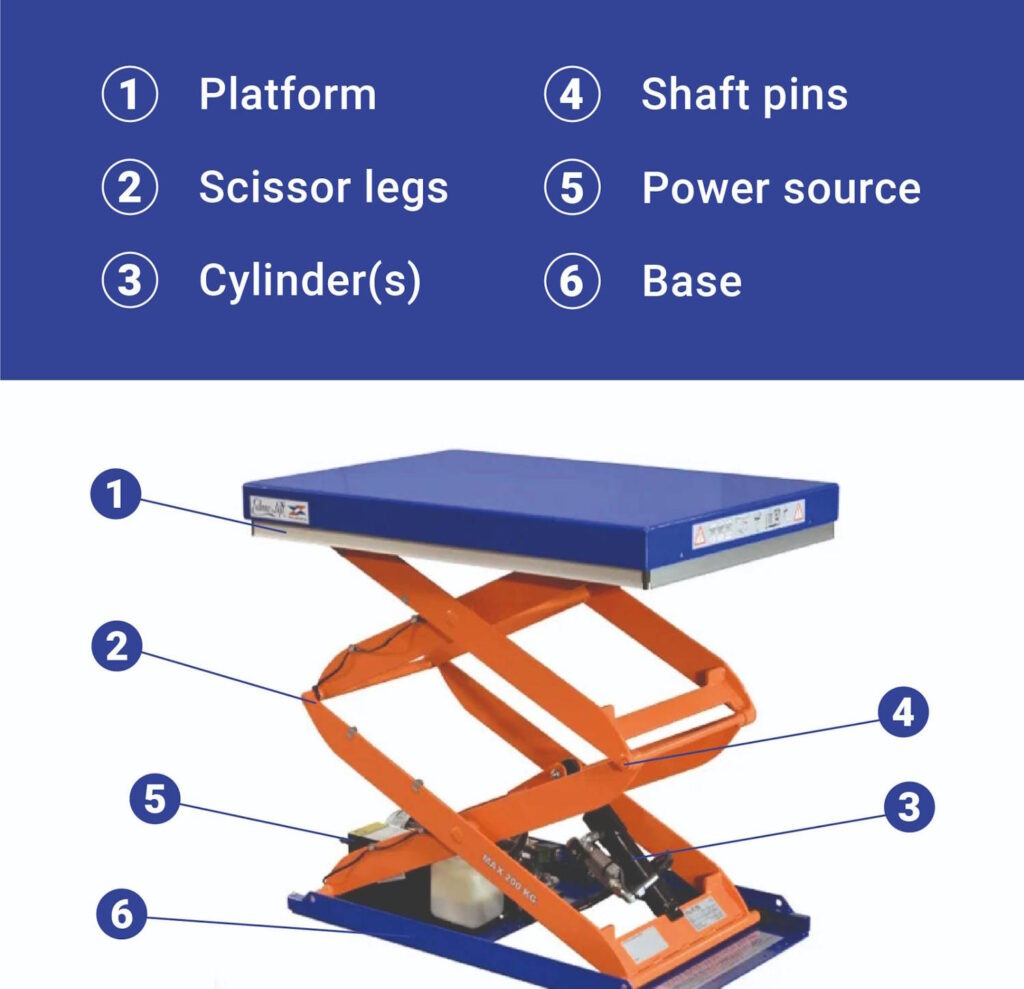

The Anatomy of a Scissor Lift Table

To properly maintain your hydraulic lift table, it’s important to have a full understanding of each part that helps it to function. In this section, you can find out more about the particular components that make up the advantageous design.

Platform

As arguably the most recognisable part of a scissor lift table, the platform is the level surface that provides a way for items to sit securely as they are propelled upwards. The flat surface helps delicate items to remain steady as they go upwards.

Scissor Legs

Designed in a criss-cross pattern, the legs of a hydraulic lift table are used to propel the table upwards. The design uses metal beams that take up very little space, yet effectively and safely reach height.

Cylinders

An essential part of the mechanism, cylinders are used to help the legs propel themselves upwards. Filled with air or hydraulic fluid, these systems can thrust powerfully, helping to move heavy weights upwards with ease.

Shaft Pins

Designed for extra stability, shaft pins can be found through the coupling at each intersection where the frames of the scissor legs meet. These additions help to ensure the legs don’t become disengaged will in motion, providing an extra level of security.

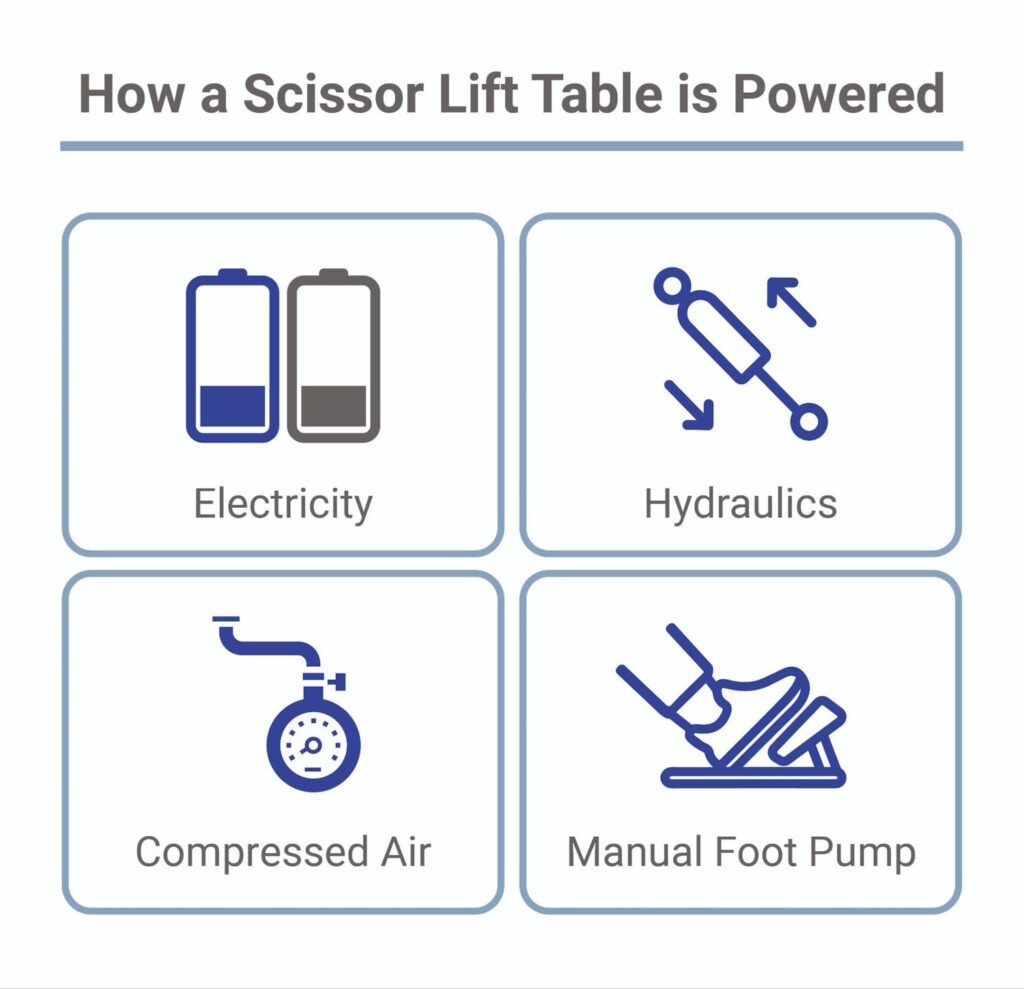

Power Source

Each type of scissor lift table will be powered to function, however, the sources of power can vary. The main power source sits within the base of the hydraulic lift table. The different sources of energy that can be used to power the mechanism include:

- Electricity (used as a battery)

- Hydraulics

- Compressed air

- Manual foot pumps

Base

As the most important part of the scissor lift table, the base is the lowermost component, usually housing the power source and other mechanisms key to its operation. This component also provides the overall stability needed to reach height safely, as a foundation that supports weight and movement. The base is a stationary component, built to be secure and not to move.

Proper Usage of Scissor Lift Tables

One of the best ways to keep your scissor lift fully functional at all times is to ensure that it is being used properly and safely. In ignoring requirements and guidelines, you can risk damaging yourself, your products and your machine simultaneously. Read on for key factors to consider when using a scissor lift table.

Understanding Capacity

It can be tempting to put an item on a scissor lift table platform that exceeds its capacity, feeling sure it won’t fall. Unfortunately, even if the item is somehow transported upwards fine, you could do irreparable damage to the scissor lift table itself. Capacities should always be adhered to, as ignoring them can lead to several further problems with the system.

Safety Restrictions

There are some things you should not put on a scissor lift table, as it can be dangerous to do so. Importantly, these tables should not be jumped on, and are usually not designed to support personnel. Persons should not travel on a scissor lift table unless it is specifically a goods-attended lift. Ensure staff does not use this equipment to stand on to both prolong the machine’s longevity and prevent any injuries.

Adequate Training

Anyone who is using a scissor lift table should be fully informed of how to do so beforehand to keep themselves safe. Training should include the capacity of the system, as well as being informed of where the emergency buttons are located. They should also know how to operate the tool fully, leading to proper usage that keeps everyone safe.

Scissor Lift Table Maintenance

As mentioned, scissor lift tables have several components and parts that are key to their function. As such, regular maintenance and inspections should be carried out to monitor the health of your system, mitigating risks of accidents and extending the life of your scissor lift table. Below are some considerations you should factor into your machine maintenance schedule.

Knowing the Requirements

As scissor lifts are available in various designs and sizes, it’s important to get a full understanding of the different types of tables that are available. Consider the power source that your lift table utilises, and adjust maintenance to adequately check that the system is fully functional and that there are no exposed wires or spillages.

Lubrication

When metal moves together, this can lead to natural wear and tear over time. Unchecked, the erosion may make it difficult for the scissor lift table to fully extend safely. Monitor your metal components for any rusting, and make sure that it is kept properly lubricated to prevent prolonged stiffness.

Visual Defects

Is something not looking quite right with your scissor lift table? Visual defects in your machine should notify you of any problems early on, so ensure that you’re not ignoring them. Any dents and bends should be monitored, alongside scratches and other damage.

Monitor for Leaks

Leaks can be a sign of damage to your scissor lift table, so it’s important to check over your machine routinely. Leaking can come from several parts of your scissor lift table, so inspect closely the cylinders and power source, to ensure no liquids or gas are escaping. If you notice any problems, it’s important to have these addressed before the system is used again.

Test Emergency Controls

As with any type of machinery, your scissor lift table needs to have fully functioning emergency controls at all times. To ensure that these systems are fully working, it is essential to carry out regular checks on your lift table. Without fully functioning test controls, you leave safety up to chance, so it’s paramount that these are routinely trialled.

Contact Professionals

If you notice something awry with your scissor lift table that you’re unsure of, the best thing to do is to contact the experts. Trained maintenance professionals can diagnose and address any issues, helping your stationary table begin to function properly once more. We would recommend routine assistance from an experienced person, particularly if you’re feeling uncertain about maintenance practices.

Regular Servicing

The best way to ensure that your scissor lift table is performing to a high standard is through regular servicing. We recommend an annual service if the scissor lift table carries goods, every six months if they are carrying people and even quarterly if the scissor lift table is being used intensively.

Other Types of Scissor Lift Tables

Not all scissor lift tables work the same way, meaning maintenance may look different for you depending on the type of equipment you have. In this section, you can learn about some other popular types of scissor lift tables and how they can be used.

Pallet Levellers

Also referred to as pallet levellers, these machines are used to help raise, lower, tilt and/or rotate pallets to move the cargo. They help items be deposited in an easier and more accessible place for staff to load or unload. Pallet levellers are often used in conjunction with scissor lift tables, creating a seamless working environment that reduces strain on physical labour.

Lifting Trolleys

On a smaller scale than scissor lift tables, lifting trolleys are a transportable type of lifting system. With wheels attached, these trolleys can be pushed across a warehouse, easily transporting goods to a new location. With a handle and breaks, these are a safe and secure way for employees to get products from A to B.

Our Services

As experts in scissor lift tables, our business can help you find the perfect solution for your company. At Scissor Lift Table, we understand the importance of keeping your employees safe, which is why we offer only high-quality and reliable equipment. With a wide range of products available, you can select the right type of scissor lift table for your space.

Our range of products is available to view on our website, helping you to get a sense of our equipment and its capabilities. For further support and tailored advice, please get in touch with us directly to find out more.