The modern scissor lift table is an innovative piece of machinery designed to reduce strain, increase productivity and overall improve the workplace. They are stationary lifting platforms that are specially designed to raise and lower heavy loads, typically used in settings where a lot of positioning, material handling and line work is involved.

But how did we get to the innovative product we see today? Join Scissor Lift Table as we delve deeper into the evolution of Scissor lifting tables.

Humble Beginnings

As long as there has been man, there has been a need to lift. For a long time, this was only accomplished with manual labour and only relied on man-made power for most of human history. But while the need to lift has always been there, so has been the concern with reducing strain on those doing the lifting.

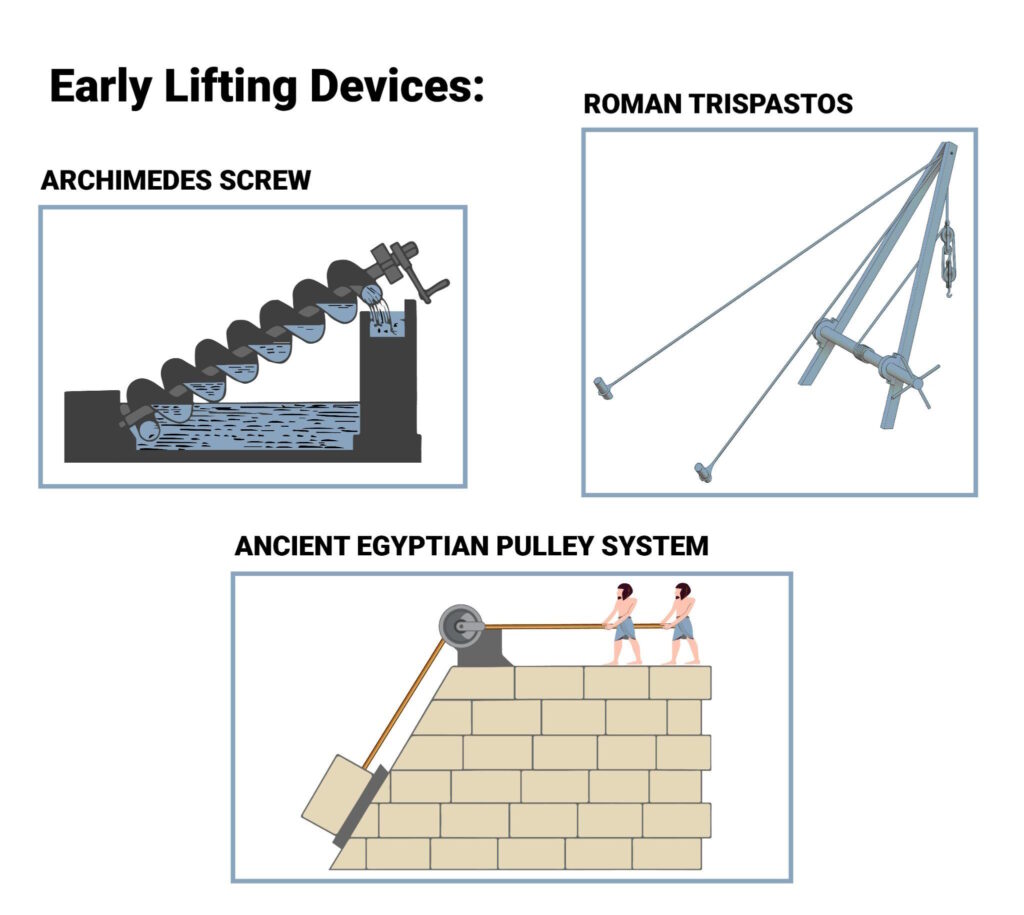

The ancient Egyptians and Mesopotamians are the first we have on record of using lifting equipment, using basic crane-like pulley systems known as shadufs to extract water from the river. The very first cranes recorded for construction use were recorded in around 500 BC by the ancient Greeks, who used them to build many of their temples and structures.

One of the earliest documented lifting devices was designed by Archimedes himself, all the way back in around 230 BC. Commonly known as the Archimedes screw, it was a type of pump that used a rotating screw-shaped blade to lift water from one lever to another.

It was primarily used for irrigation applications, and while it did not carry people or goods, it was a significant step forward in terms of lifting devices and paved the way for centuries of development. It was so innovative in fact that the Archimedes screw model is still commonly used today.

The Romans built on the ideas of the Greeks to build trispastos, triple pulley systems that significantly improved productivity. After the fall of the Roman Empire, many of these designs were lost, and it wasn’t until the Industrial Revolution that we saw further large strides in development.

The Industrial Revolution

The Industrial Revolution brought with it developments in almost every field, and in the world of lifting tables, this is where mechanical force began to be used. Steam power started to be used more prominently, which could help to power technology and stop it from relying so heavily on human power. In 1835, a belt-pulled lift table called a winch machine was first installed in a British factory, and the first industrial hydraulic lifting tables soon followed starting in 1846.

Recent Innovations

The concept behind a scissor lift table is a simple and effective one, utilising linked, folding supports in a crisscross pattern that will raise and lower payloads vertically. Since they became widely available, most of the enhancements in the field have been to improve the design, materials and operational capabilities, which can help to ensure the best and most efficient performance.

One of the biggest developments in the world of scissor lift tables has been the materials used in their construction. Development of things such as high-strength steel alloys and reinforced structures have increased the capacity of scissor lift tables while also maintaining structural integrity. This means they can now handle increased loads without fear of breaking.

There has also been plenty of development to increase the safety of scissor lift tables. This includes emergency stop buttons and non-slip platforms, which can quickly stop the scissor lift table and prevent loads from slipping around and potentially falling off and either breaking or hurting a worker.

Explore Our Scissor Lifting Table Range

Here at Scissor Lift Table, we are one of the leading manufacturers of scissor lift tables and other related lifting products. All of our products are built in our UK workshop, meaning you can expect the quick delivery of your ideal solution from industry experts.

The main product we are able to offer you is scissor lift tables, available in assorted capacities, platform sizes and heights, meaning by working with us you can find the best solution for your exact needs. Our stock of scissor lift tables includes single, double vertical, double horizontal and low-profile scissor lift tables, so you can rest assured that you will find a model that works for you.

We also stock quality lift and tilt tables, ideal for precisely positioning loads of all types with a capacity of up to 1500kg. If you’re looking for something on wheels, our lift trolleys are perfect for warehouses and workshops where you need to lift loads to various spots.

Scissor Lift Table are also able to provide reliable work positioners, with a range of capacities, platform sizes and maximum heights as well as pallet levellers to make working with pallets easier and safer.

Contact Us Today For Scissor Lifting Tables

Now that you’ve found out a bit about the evolution of scissor lifting tables, and some of the options we have, work with Scissor Lift Table to find a solution to fit your precise needs. The best thing about the products available from us is their versatility, helping with everything from making a great adjustable workbench for maintenance to stacking timber at an adjustable height to avoid bending and stretching.

If you’d like to find out more about any of our products, or arrange a purchase, get in touch with us today.